In 1983, SCHUNK the competence leader for clamping technology and gripping systems introduced the world's first standardized industrial gripper on the market. The "industrial hand, "has been the former designation, and has been the starting point for a fast development of gripping systems which still continues today.

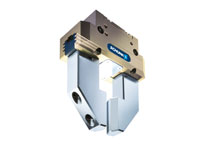

At the beginning of the 1980s, Heinz-Dieter Schunk, the Managing Partner of SCHUNK GmbH & Co KG in Lauffen had a brilliant idea. Inspired by the just starting boom in the in-dustrial robotics he noticed how bulky the individually developed gripping tools on the ro-bots were. Due to the connected pneumatic lines, the modules sometimes had extreme interfering contours. For him it was clear: in order to make robots and other handling sys-tems more successful, grippers are required, which are more compact, lighter, precise, and if possible more cost-efficient than any other solution which was available to date. In 1983, SCHUNK introduced the world's first standardized industrial gripper on the market. It was comparably light and disposed of integrated air channels. Graduated sizes enabled the de-signers to achieve particularly efficient solutions. The "industrial hand" from SCHUNK has been the starting point for a thirty-year-story of success. SCHUNK grippers are known for precision, longevity and robustness. They are synonymous for process stability and effi-ciency in assembly and handling.

From a simple gripper to an intelligent high-tech module

SCHUNK continually sets new standards for grippers with their pioneering spirit. The pa-tented multi-tooth guidance which SCHUNK introduced in 2000 is still considered today as a benchmark in gripping technology. Since it is used in modules such as the world's well-known PGN-plus universal gripper, it is particularly compact, and is also fast and precise. A short time later in 2006, SCHUNK again performed pioneering work, and introduced a pro-gram for mobile gripping systems. In addition to mechatronic rotary units, and efficient lightweight arms, it comprises the industry-proven SCHUNK SDH dextrous hand, a sensitive three-finger hand, and is suitable for various gripping scenarios, and perfect for applica-tions in the field of service robotics. The latest development of this business unit is a 5-finger hand. It is amazing how it resembles in size, shape, and mobility to its human model.

But SCHUNK also paved the way for new types of grippers in the field of industrial robotics. In 2008, the market leader for gripping systems combined three features lightweight de-sign, mechatronics and modularity to its LEG electric long-stroke gripper. In 2011, the company presented a vast program of electrically actuated modules in the framework of their "Mechatronik3" initiative on the market: the electric EGP small parts gripper with the world's most compact performance, the adaptable EGA long-stroke gripper, and the intel-ligent and sensitive WSG parallel gripper. The latest gripper generation indicates the direc-tion of this trend. Modern high-tech components allow a unique measure of flexibility at handling processes. With one single module, manifold gripping scenarios can be imple-mented. The powerful and sensitive modules can handle various components one after the other, and without any set-up time. At every grip the finger position and gripping force are individually adjusted to the workpiece. The required sensor system, the control and regu-lation technology, as well as a web browser for communication with the higher-ranking system components are already integrated in the gripper. Via intuitively operable pro-gramming interfaces, the modules can be easily integrated, controlled and maintained, and no additional software has to be installed via internet.

The world's largest standard program for gripping systems

When we compare the modern SCHUNK grippers with the industrial hand of 1983, the enormous development step in gripping technology of the past 30 years is obvious. Simple, mechanic components developed to intelligent, powerful, and highly efficient high-tech modules, which allow the users to implement flexible and closely integrated handling pro-cesses. Today, SCHUNK offers more than 10.000 components to the world's largest standard program for gripping modules and a module program for gripping systems which is unique in its own way. It comprises grippers and rotary modules, linear axes, speedy Pick & Place units, mobile gripping systems, and compact robot accessories. Over the years, many intersections of the SCHUNK clamping technology program were formed, and the user benefits from considerable synergies from both business units when using the SCHUNK modules.

Milestones of the 30-years-history of SCHUNK grippers:

| 1983 | SCHUNK Industrial hand – the first standardized industrial gripper |  |

| 2000 | PGN-plus – the first gripper with patented multi-tooth guidance | |

| 2006 | SDH – industry-proven 3-finger hand for service robotics | |

| 2008 | LEG – a symbiosis of lightweight design, modularity, and mechatronics | |

| 2010 | MPG-plus – the miniature parallel gripper with the most compact performance | |

| 2011 | EGP – the electrically actuated small parts gripper with the most compact performance | |

| 2012 | 5-finger hand – almost as talented as its human model | |

| 2013 | CGH – the first standardized lightweight gripper with CFC housing |

Captions:

| Industrial hand | 1983: SCHUNK presents the "industrial hand" on the market. The world's first standardized industrial gripper. |  |

| PGN-plus | 2000: The PGN-plus universal gripper was the first gripper with multi-tooth guidance. |  |

| SDH | The SDH combines the advantages of industrial grippers with those of a human hand. |  |

| 5-finger hand with LWA 4P | The 5-finger hand from SCHUNK (shown here at a Powerball Lightweight Arm LWA 4P) is almost as talented as its human model. |  |

Our contact details:

Satish Sadasivan

SCHUNK INTEC INDIA PRIVATE LIMITED

No 80 B, Yeshwanthpur Industrial Suburbs,

Bangalore – 560022, India

Ph.: 080-40538999

Fax: 080-40538998

Email: info@in.schunk.com

Web: www.in.schunk.com